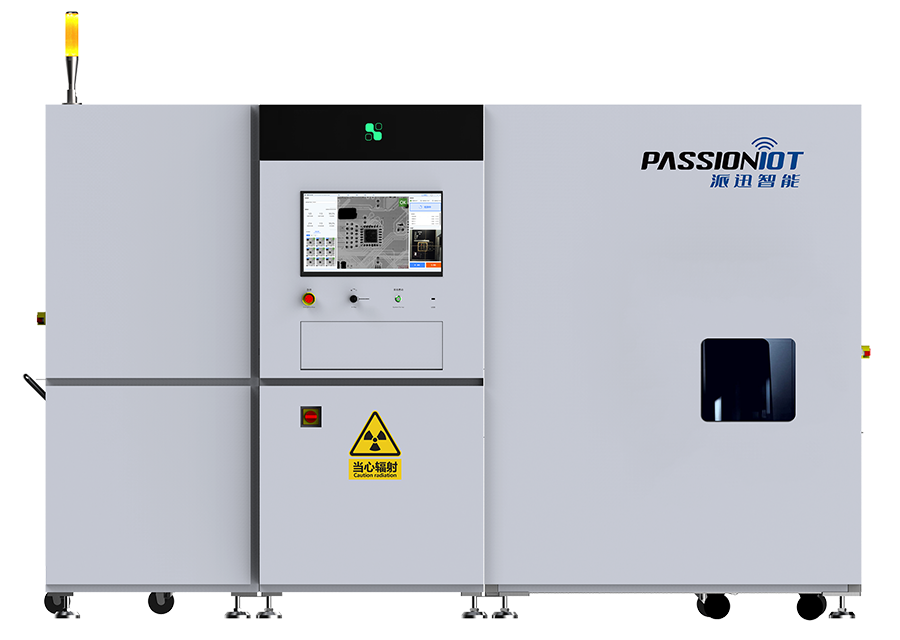

Manufacturing businesses that handle Surface Mount Devices (SMD) require reliable and efficient systems to manage their inventory and counting processes. In particular, the x-ray reel counter has become a crucial tool for companies that need to track high volumes of components. The PassionIOT SMD reel counter X-ray provides an advanced solution to this challenge, offering precise, high-speed counting capabilities. In this article, let’s explore the significant advantages of using an x-ray reel counter in industrial settings.

Increased Accuracy and Speed in Component Counting

The primary benefit of using the x-ray reel counter is its remarkable accuracy in counting SMD components. Unlike traditional manual methods, this technology provides 99.99% accuracy, ensuring that the counting process is precise and reliable. With the ability to count components in just 10 seconds across a range of 7–15 inch reels, the PassionIOT SMD reel counter X-ray significantly reduces the time spent on manual counting and minimizes the likelihood of errors. This speed and precision help businesses streamline their operations and maintain product quality.

Seamless Integration with Existing Systems

One of the advantages of the PassionIOT SMD reel counter X-ray is its seamless integration with existing business systems such as ERP, MES, and WMS. By easily connecting to these platforms, the x-ray reel counter improves traceability and data management across the entire supply chain. The PassionIOT system also reduces the need for manual data entry, decreasing the risk of human error. This integration ensures that businesses can monitor and track their components with minimal intervention, enhancing overall efficiency and productivity.

Enhanced Process Efficiency for High-Demand Environments

The x-ray reel counter excels in industrial environments where continuous and high-volume counting is required. The PassionIOT SMD reel counter X-ray is built to handle demanding tasks, offering uninterrupted batch processing and reliable performance under challenging conditions. Whether it’s in a high-paced factory or a busy warehouse, this system maintains smooth operations with minimal downtime. The technology’s ability to provide continuous and accurate counting makes it an essential tool for businesses looking to optimize their processes.

Conclusion

The PassionIOT SMD reel counter X-ray is a highly efficient and accurate solution that can significantly improve the component counting process in SMD manufacturing. With its exceptional accuracy, quick counting speed, and seamless integration with existing systems, businesses can achieve better productivity, reduce errors, and improve overall efficiency. For industries that require precision and reliability, this technology offers a valuable solution to meet the demands of modern manufacturing.